When a solid-state drive fails inside a server, the impact is immediate and severe.

RAID Recovery Services recently received a case involving a 200 GB enterprise-class SAS SSD that malfunctioned and triggered a critical server crash. The outage caused partial data loss and operational downtime.

After initial troubleshooting confirmed the SSD was no longer recognised by the system, the client engaged our team for professional support.

Our engineers were tasked with evaluating the fault, determining the root cause, and restoring access to the lost data as quickly and safely as possible.

Receiving the Damaged SSD

After reviewing reputable providers, the server administrator engaged RAID Recovery Services for an evaluation. Our customer service team guided the client through packaging to ensure safe transit.

The SSD was placed in an anti-static bag and cushioned with shock-absorbing material to mitigate electrostatic discharge and physical impact.

On arrival, our recovery team logged the case and began diagnostics to assess the extent of the failure.

Shortly after the incident, a second SSD in the mirrored set also failed, removing access to the replicated data and rendering the server inoperable. This dual-fault scenario created a complex recovery requiring targeted hardware repair and advanced data reconstruction.

Diagnostic process: visual and instrumental analysis

Our engineers followed a structured two-stage approach to isolate the root cause. Each step informed the recovery strategy.

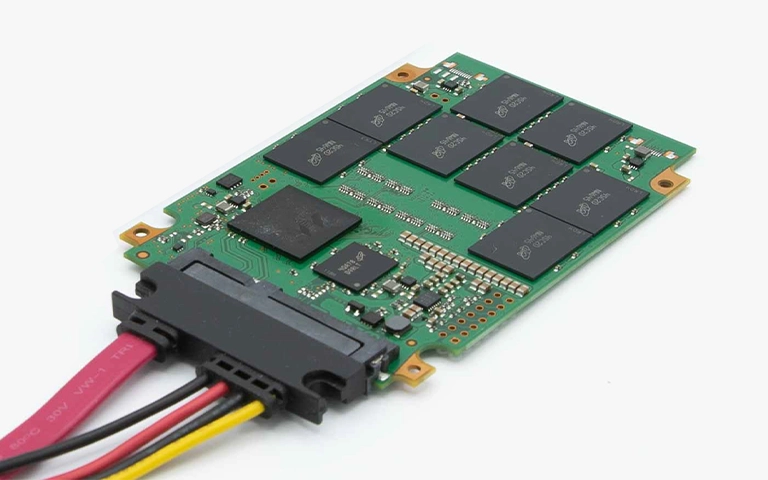

Visual inspection: The SSD’s electronics were examined under a microscope to identify physical defects. Heat-stressed semiconductors often show discolouration, hairline cracks, or burn marks. The PCB displayed clear evidence of overheating.

Instrumental diagnostics: We tested voltage regulators, continuity, and power rails to validate electrical stability. Results confirmed overload and heat damage to the PCB, while the NAND memory remained intact.

These findings indicated the data could be recovered using a chip-level method. For related scenarios, visit our article on RAID hard drive failure.

Data extraction and recovery

With the NAND memory intact, our engineers performed a chip-off recovery to access the stored data directly. This approach enables reading from the memory chips even when the PCB or controller has failed.

The NAND packages were carefully desoldered from the SSD using precision heat control to avoid thermal stress and pad lift.

Each chip was interfaced with a hardware programmer so our specialists could extract the raw data blocks at scale.

Using advanced recovery software, the team rebuilt the SSD’s original logical structure and mapping tables to translate RAW dumps into readable files.

All restored data underwent checksum verification and spot sampling to confirm completeness and consistency, ensuring no corruption or mismatch remained.

For a closer look at how similar workflows operate, visit Troubleshoot RAID Failure.

Successful recovery outcome

Following reconstruction, all user data was retrieved and verified. Our engineers confirmed that each recovered file was accessible and free from corruption. The client joined a remote verification session to ensure the results met operational requirements.

After approval, the data was securely copied to a new SSD and returned to the client. The server was brought back to normal service with no further loss or downtime.

Fast turnaround times for business-critical data

Preventing Future SSD Failures

Enterprise SSDs are designed for speed and reliability, but continuous heavy workloads can accelerate wear. Proactive controls reduce the risk of critical incidents.

Monitor temperature routinely. Maintain adequate airflow and cooling in racks to prevent overheating.

Track SMART data. Use monitoring tools to identify early signs of degradation or bad blocks.

Distribute workloads. Avoid sustained high write cycles on a single drive to extend lifespan.

Schedule regular backups. Keep redundant storage so operations continue if a drive fails unexpectedly.

For wider risks across enterprise storage, see our article on Enterprise Hard Drive.

Professional SSD data recovery services

Recovering data from a failed SSD demands precision, experience, and the right tooling. In this case, accurate diagnostics and chip-level reconstruction enabled our engineers to restore all critical data safely. Attempting recovery without professional equipment could permanently destroy what remains.

If your SSD or server has failed, engage RAID Recovery Services for expert assistance. Our specialists handle enterprise devices affected by electronic faults, controller malfunctions, or firmware corruption with a proven track record.

For related cases, visit Server Crash to see how professional recovery helps restore system stability.

Trust the experts with proven results

Frequently Asked Questions

What causes SSD failures in enterprise servers?

Common triggers include overheating, sustained heavy workloads, power fluctuations, and controller faults. Continuous read/write activity without adequate cooling accelerates wear and can lead to PCB damage.

Can data be recovered if an SSD’s PCB is damaged?

Often yes. If the NAND memory remains intact, engineers can perform a chip-off procedure to extract the data and reconstruct the volume safely.

How long does SSD data recovery take?

Timeframes depend on the extent of physical and logical damage. Most enterprise SSD recoveries at RAID Recovery Services are completed within 2 to 5 business days following evaluation.

What is RAW data during SSD recovery?

RAW data is the unprocessed output read directly from NAND chips. It requires reconstruction into the original file system and folders before an operating system can read it.

How can I prevent SSD-related server crashes?

Monitor drive health, maintain proper airflow and cooling, distribute workloads, and implement RAID redundancy with regular backups. These measures reduce downtime and minimise data-loss risk.